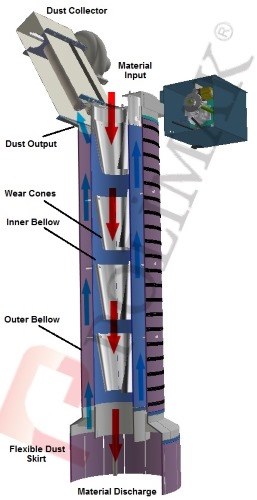

Stockpile loading spouts are used for dust free discharging of powdered and granular bulk solids to stockpiles. Free flowing dry bulk solids in powder and granule form are easily transferred from silos, hoppers, containers, screw feeder to stockpile basement. Built in flexible dust skirt prevents the dust emission outside of the loading region.

Operation of Stockpile Loading Spouts

At the beginning of stockcpile loading, spout is lowered towards the ground and stops at the bottom. Flexible dust skirt located at the bottom of spout keeps the dust content inside the loading area. During material discharge, spout dust skirt provides a closed containment for dust. Dust collection unit vacuums any fugitive dust in the region and prevents dust emission to the surrounding. Collected dust is then sent back to the product stream continuously and material waste is prevented during loading. Built in level sensors monitor the product level below the loading spout dust skirt. When the material level increases, spout is retracted upwards automatically with winch system and it maintains a space to let the material flow rapidly. After stockpile loading is finished, product discharge valve above the loading spout is closed. System waits for few seconds to complete product flow and to collect remaining dust by dust collector. Loading spout automatically retracts to the top position afterwards.

Advantages

– Dust free loading

– Dust free working region, prevention of dust pollution, ensure port and environmental safety.

– Suitable for different bulk solids conveying and storage systems

– Loading is possible from different equipment like silo, hopper, screw feeder, conveyors etc.

– Built in flexible dust skirt to prevent dust emission outside of the loading region.

– Extensive range of models are available for wide range of needs

– No spillage and no product waste

– Food grade loading spouts are available

– Simple operation

– Easy maintenance

Handled Materials

Cement, fly ash, mining minerals, calcium carbonate, pvc, plastic pellets, plastic powders, alumina, bentonite, bauxite, coal, cement clinker, gypsium, kaolin, limestone, marble powder, soda ash, quartz, urea, sodium sulphate, wheat, flour, animal feed, seed, corn, rice, sugar, salt and similar powdered and granular dry bulk solids.