Closed Vehicle Loading Bellows

Closed loading bellows are used to fill tanker trucks, closed containers, barges and ships with closed containers. They utilize poliurethane coated discharge cones that fit vessel inlet to prevent any dust emission during vehicle loading. After tanker filling is started, built in vacuum fan evacuates the air trapped in the vessel to increase product flow rate. This vacuumed air passes through the dust collector. Any dust content is trapped by filter units and sent back to the tanker with the help of automatically operated pulse jet valves. Level sensor located at the bottom monitors the product level in the bulk tanker. When the tanker is full, level sensor sends a signal to stop loading. Product discharge valve above the loading bellow is closed. System waits for few seconds to complete product flow and to collect remaining dust by dust collector. Loading bellow automatically retracts to the top position. Depending on the process requirements, loading amount can also be controlled by other systems such as truck weighing scales. When the determined amount of product is filled, weighing system sends a s signal to control panel of loading bellow and loading is stopped automatically.

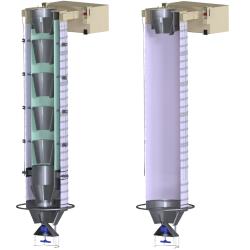

Open Vehicle and Stockpile Loading Bellows

Open vehicle and stockpile loading bellows are used to load bulk material to open region such as flatbed open trucks, ships and stockpiles. Automated retraction mechanism and flexible dust skirt are key elements of open loading bellows. Flexible dust skirt is located at the bottom of loading bellow. During material discharge, it provides a closed containment for dust. Dust collection system vacuums any fugitive dust in the region and prevents dust spreading to surrounding. Collected dust is sent back to the product stream continuously and no material is wasted during loading. Built in level sensors monitor the product level below the loading bellow. As the level increases, bellow is retracted upwards automatically and it maintains a space to let the product discharge rapidly. When loading is finished, product discharge valve above the loading bellow is closed. System waits for few seconds to complete product flow and to collect remaining dust by dust collector. Loading bellow automatically retracts to the top position afterwards.

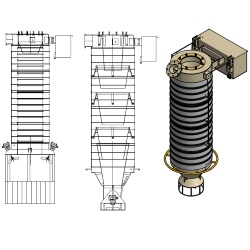

Combined Loading Bellows for Tanker Trucks and Open Trucks

Combined telescopic loading bellows are used for dust free loading of powdered and granular bulk solids both into tanker trucks and flatbed open trucks. Free flowing dry bulk solids in powder and granule form are easily transferred from silos, hoppers, containers, screw feeder to trucks. There exists flexible dust skirt and poliurethane coated discharge cone together at the same loading bellow unit. Combined loading bellows are suitable for applications where incoming truck types vary.