Loading bellows are coupled with product feeding equipment. Depending on application requirements, wide range of bulk solids handling equipment can be utilized for feeding loading bellows.

Butterfly Valve

Butterfly valves are generally installed below silos or hoppers. Product discharge outlet can be completely opened or closed in short time with the help of butterfly valves installed above loading bellows. In truck filling applications, butterfly valves serve to control amount of product loaded.

Slidegate Valve

Slidegate valves are generally located at the silo and hopper outlets. Pneumatic piston controlled slidegate valves are used to start and stop product loading in short time. Screw and gearbox controlled slidegate valves can be used to adjust bulk material loading speed by adjusting gate opening size.

Screw Conveyor

Screw conveyors are used for transferring bulk solids from hoppers, silos or plant machinery to loading bellows with controlled speed and capacity. Depending on loading area conditions, screw conveyors can be used to move the bulk solids to higher levels before entering into loading bellows to save some height for trucks.

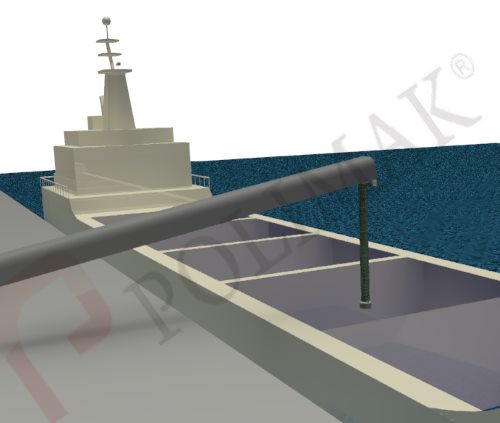

Belt Conveyor

Belt conveyors can be utilized to transfer bulk materials to loading bellows. They are generally preferred in open regions and stockpile loadings. Special designed intermediate hoppers are used for smooth discharge of bulk materials from conveyor belt outlet to loading bellow. Depending on dust load of the conveyed material, extra dust collectors can be utilized.

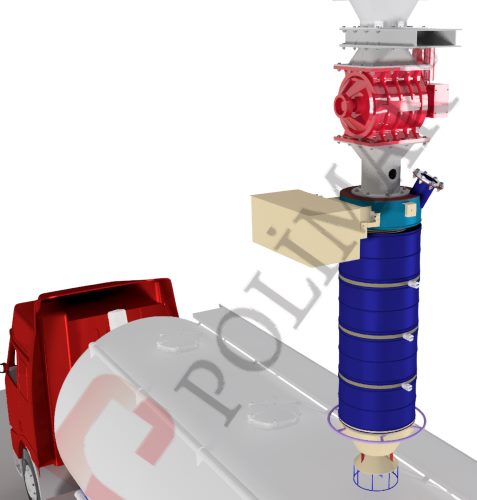

Rotary Valve

Rotary valves are used for discharging bulk materials from silos and hoppers with controlled speed into the loading bellow systems.

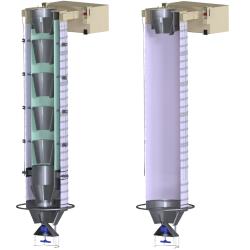

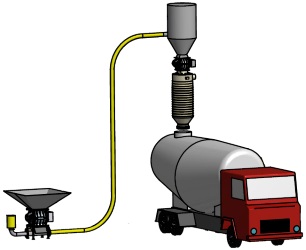

Pneumatic Conveying System

Pneumatic conveying systems are preferred in plants where loading area is far from the bulk material storage equipment. Pneumatic conveying systems transfer bulk materials from storage units to loading bellows within pipelines with air pressure or vacuum. Pneumatic conveying capacity is determined and equipment is selected with respect to transfer distance and loading bellow capacity.

Airslide Conveyor

Airslide conveyors are utilized in high capacity loading of fine powdered materials such as cement loading to tanker trucks in cement plants. Loading bellows installed are below the outlet of air slide conveyors. Bulk material is fluidized within airslide conveyors with the help of pressurized air coming from the bottom. By the help of gravity, they move towards the downside direction. The inclination of airslide conveyor directly effects the flow speed.